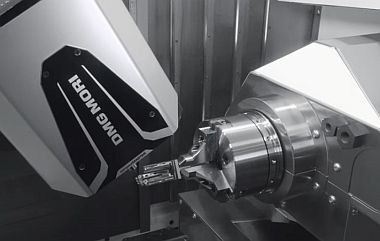

New Compact Turn & Mill Offers 6-Sided Machining -- Excellent for Small, Complex Parts

The continuing trend towards increasingly complex workpieces requires extremely versatile manufacturing solutions. With the NTX turn & mill series, DMG MORI has a product range that enables productive manufacturing of artificial bones or implants in demanding industries and especially in medical technology.

Now the machine tool manufacturer is presenting the NTX 500. The most compact model in the series offers a working area for workpieces up to ø 120 x 558 mm.

As with its larger sister models, the heart of the NTX 500 is a high-speed turn & mill compactMASTER spindle with a length of only 250 mm. Its turning speed of 42.000 min and a swivel range of ± 120°. The swivel range offers absolute flexibility in 5-axis simultaneous machining -- even with small diameter precision tools. The Y-axis moves by 150 mm.

In addition, the turn & mill center allows highly productive 6-sided complete machining of demanding workpieces.

The NTX 500 features a lower turret with 16 tool positions, including a Y-axis with 60 mm travel. This allows parallel cutting to the turn & mill spindle in 4-axis machining, drastically reducing cycle times. The tool magazine can be loaded during machining and offers space for 38 tools. Optionally, 76 or 114 tool positions are available.

Automation solutions are available for the NTX 500 with an integrated bar feeder (right side bar feeder) and an integrated robot (IMTR) for unmanned production over long distances. The former is designed for bar stock up to ø 40 mm. The integrated robot allows automatic workpiece unloading from the main and counter spindles.

Want more information? Click below.

Rate this article

View our terms of use and privacy policy ::m::